Project Description

Semi-automatic line for filling BIG-BAGs

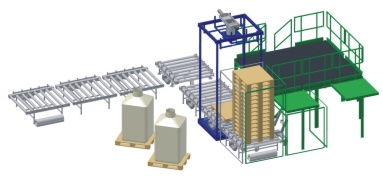

Here is an example of the integration of a simple BIG-BAG filling station into a semi-automatic line.

The device assembly consists of:

- pallet stackers, after loading, individual pallets are fed to the station for filling bags

- own filling station for BIG-BAGs, the operator manually clamps the empty bags and starts their automatic filling

- bag forming equipment, the bag is inflated before being filled

- shaking device, for better use of the space in the bag, the material can be shaken during filling

- roller conveyors, the movement of pallets on the entire line is ensured by means of powered roller conveyors, which ensure the transport of the filled bag to the collection position, from where the bag is taken away with the help of a VZV.

The assembly of the equipment can be adjusted according to the specific specification, according to the properties of the filled materials and the spatial possibilities of the customer.

The individual components of the line are controlled by a control system that ensures the movement of pallets and filled bags, accurate and fast filling, printing of weight tickets for individual bags.