Project Description

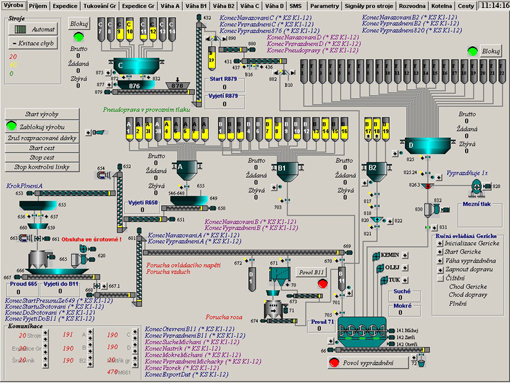

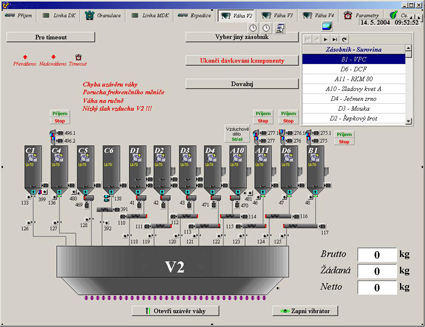

Automation of production (VKS, silo)

Control system – visualization on PC

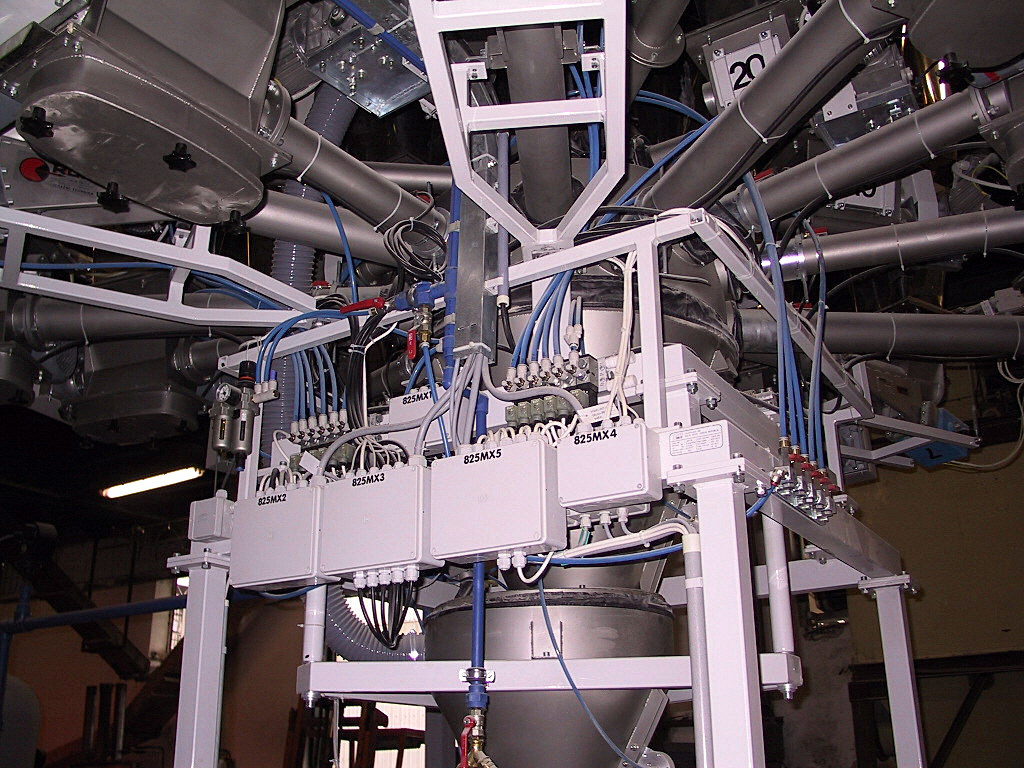

We provide design, production, delivery of HW and SW, sensors and other parts of the control system of technological processes or individual devices. The core of the control system is a PLC, visualization is realized on a PC or operator panel. We mainly work with the following systems: Siemens, Teco, Beckhoff, Schneider,…

The control system itself is designed as multi-user, which means that the technology can be controlled and monitored from several workplaces, even according to the level of access priorities. In many applications, visualization on a PC is realized by the Control Web program. In other cases or at the customer’s request, we use the WinnCC visualization tool within the new TIA portal.

The control system emphasizes increased safety and reliability. Therefore, the main algorithms ensuring the operation of the application and having an impact on emergency situations are consistently located in the PLC, which to a certain extent works independently of the visualization PC. In the event of a failure of the superior PC during operation (network failure, etc.), it is then possible to follow up and complete the operation in progress.

Operátorská pracoviště jsou vybavena operačním systémem WINDOWS .

Operator workstations are equipped with the WINDOWS operating system.

The database may contain information:

- of all weigh-ins in which data on the weigh-ins are recorded

- components, date and time of weighing

- receipt, in which data on each received (stocked) raw material is recorded

- expeditions, in which every delivery of mixtures is recorded, a list of customers, carriers, – drivers and other data necessary for managing the agenda of the expedition is kept here

- of failure states, in which all failure and other states are recorded

- interventions and commands made by the operator

- diagnostics and identification of machine faults with monitoring of engine hours

- changing the states of binary and analog signals

- the course of analog signals, from which it is possible to display, for example, the trends of all monitored signals

- of production, which precisely maps the time course of individual production steps

- of transport routes which precisely maps when which route was started and when it was stopped and enables the compilation of permitted routes

raw materials, mixtures, allocation of storage tanks and raw materials - recipes including the creation of new recipes

- a list of production orders, whether produced or not yet produced mixtures

- parameters of scales, feeders and other technological parameters

- another database

For more details, see the attached catalog sheet or on request.